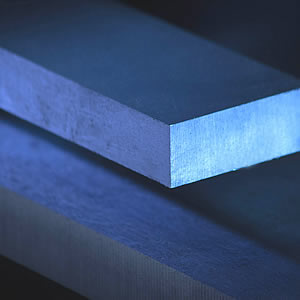

We are a stockist of high-quality titanium flat bar products in a range of incremental sizes to suit your specific engineering requirements.

Differences

There is little fundamental difference between titanium flat and plate products apart from the size. In essence, titanium flats usually are less than 8 inches wide, but the chemical and mechanical characteristics are mostly the same. Titanium is 45% lighter than steel and yet retains its strength. Additional alloying elements such as aluminium and vanadium introduced during the alloying process improves the mechanical properties of the titanium alloy. We also supply commercially pure titanium which is the unalloyed version.

Processing

We process your titanium flat bar to specific cut lengths thanks to our in-house processing teams. Typical applications for titanium flat bar products include motorsport, aerospace and automotive. However, the alloy lends itself well to a broad range of general engineering applications where high strength low weight ratios are required. Titanium is more expensive than aluminium as the alloy is more expensive to produce, so the choice for the customer will ultimately come down to cost versus performance.

Choosing between aluminium and titanium

Titanium is around two-thirds heavier than aluminium alloys but is a much stronger material, so less material is required. In truth, the necessary amount of titanium in comparison is considerably less. Therefore, both aluminium and titanium have their place depending on the particular application in mind.

We stock Titanium Flats in a variety of grades.